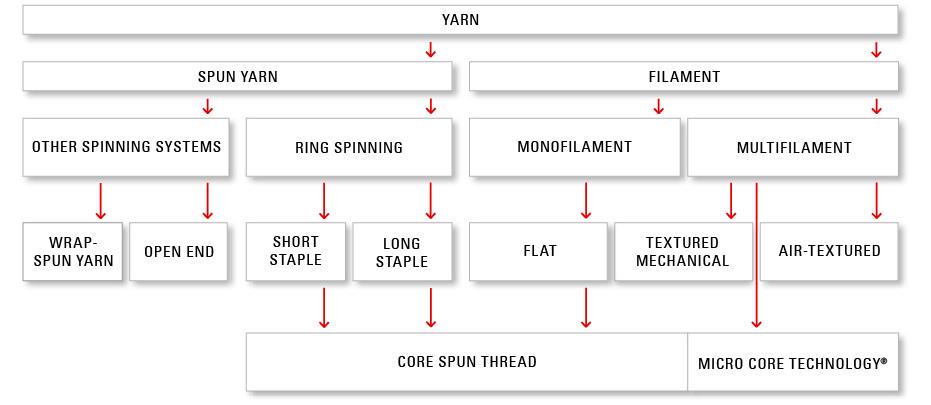

Sewing thread construction

Not all sewing threads are equal, because every sewing application requires the appropriate raw material in combination with the corresponding sewing thread construction. This is why there are various sewing thread technologies available – each sewing application requires a suitable sewing thread. We have had a significant influence on the production of many sewing threads.

Overview of the most important sewing thread constructions:

Micro Core Technology® (MCT)

The Micro Core Technology manufacturing process developed by Gütermann is not comparable to any existing sewing thread design. It is the first core spinning process based on microfilament polyester, making threads of the highest quality which also offer optimum process reliability. The result: Extremely uniform and smooth seams with an exceptionally fine thread cross-section and silk-like shine. The textile surface character of our MCT threads is formed by loops known as micro-loops. MCT threads also have a high mechanical load capacity and are absolutely safe for use with all sewing machines.

Smoother, finer, shiner –

Micro Core Technology® advantages at a glance

More robust

- no fraying out

- resistant to alkaline and basic washing enzymes

- temperature-resistant

Cleaner

- no abraison

- no fiber deposit on material or machine

Finer

- sewing threads are finer, visible in cross section

Kinder to the environment

- better enregy efficiency due to Micro Core Technology®

- fewer CO2 emissions

- minimal textile production waste

More uniform

- no thin or thick places

- enhanced anti-friction properties and uniformity of the seam

- absolutely reliable on automatic sewing machines

Brilliance

- surface bundles and reflects light consistently in one direction

- particularly shiny with a silk-like sheen

Smoother

- no losse fibre ends

Softer

- mirco-loops around the thread core

- crosswise elastic and flxible